The Truth About Epoxy Garage Floors:

What Every Homeowner Should Know

Your garage is one of the most used spaces in your home — yet often the most overlooked. Between New England winters, salt, car fluids, and daily wear, concrete floors take a beating. That’s where epoxy flooring comes in. But not all epoxy floors (and not all installers) are created equal. At Revel Garage Solutions, we want you to know exactly what you’re investing in because the right system can last for decades, while the wrong one can start peeling within months.

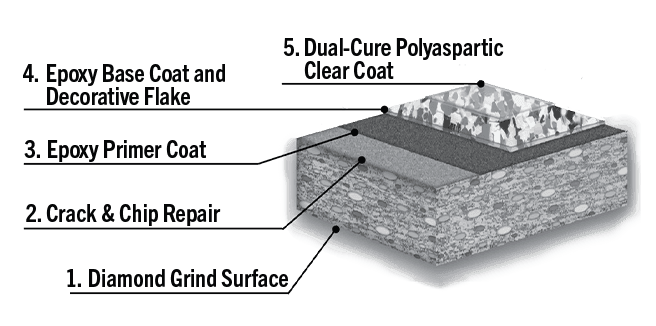

WHAT MAKES A BEST PRACTICE COATING? The Foundation of a Long-Lasting Floor

Epoxy flooring isn’t paint — it’s a professional-grade resin coating system that bonds directly to your concrete, creating a rock-solid surface that resists damage, stains, and cracking that can last a lifetime when best practices are followed.

RESIN COATINGS VS. PAINT

- Unmatched adhesion: It bonds tightly to your floor, creating a foundation that won’t lift or peel.

- Chemical & stain resistance: Spills, salt, and oil? No problem.

- Durability: Built to handle daily traffic, tools, bikes, and vehicles without chipping or wearing out.

So you know this is not paint.....now what? What few people know is that this is not a regulated industry and anyone can install whatever they want regardless whether they know better or have your best interests in mind.

WHAT IS REQUIRED TO PROPERLY INSTALL A RESIN-BASED COATING SYSTEM?

- Assessing the Space: Inspecting for areas of concern to select the right system for your project.

- Preparing the surface properly: to prevent hot tire pickup (a common failure for improperly prepped floors)

- Correcting defects: repairing cracks, divots and chips

- Selecting the right materials for the job: Different resins have different final properties when cured and it is up to the installer to select the correct materials for each layer (primer, base coat, clear or top coat).

WHAT ARE WE LOOKING FOR WHEN WE ASSESS YOUR SPACE DURING A CONSULTATION?

- Access restrictions (for example, if a basement is being coated)

- Evidence of pitting or spalling, cracks and other relevant damage before we lay coating system

- Moisture vapor evidence based on visible efflorescence and position of the slab relative to the gradethese

factors will inform which system is best for your project (standard primer, moister primer, urethane floor or alternate modular tile). High levels of moisture vapor can cause resin floors to separate from the concrete if steps are not taken to use the right materials during the install process. This is especially a concern in New England with our numerous older homes and wet climate.

THE REVEL PROCESS: Built to Last

- Prep & Grind: We diamond-grind every surface to open the pores of the concrete so that the first layer of resin absorbs into the concrete’s capillaries. Please note: pressure washing or acid etching are insufficient and a red flag. If an installer offers to do this, walk away.

- Repair & Patch: Any cracks or pits are filled and permanently corrected before laying any resin.

- Epoxy Basecoat & Decorative Broadcast: Industrial-grade epoxy creates a strong foundation. Choose your broadcast material and color blend for custom style.

- Epoxy Primer: (Insert primer details here)

- Polyaspartic Topcoat: UV-stable, protective, and glossy finish that seals the deal.

WHY HOMEOWNERS TRUST REVEL

- Trained technicians with decades of combined experience.

- Free design consultations and transparent quotes.

- Floors backed by product and workmanship warranties.

- Locally owned and operated in Wilmington, MA.

- Proudly serving Eastern Massachusetts and Southern New Hampshire homeowners year-round — yes, even in winter!

Before and After

|  |

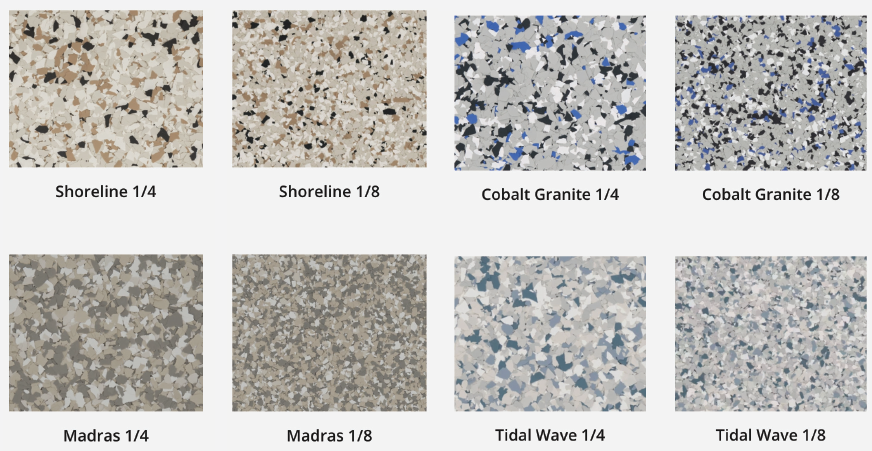

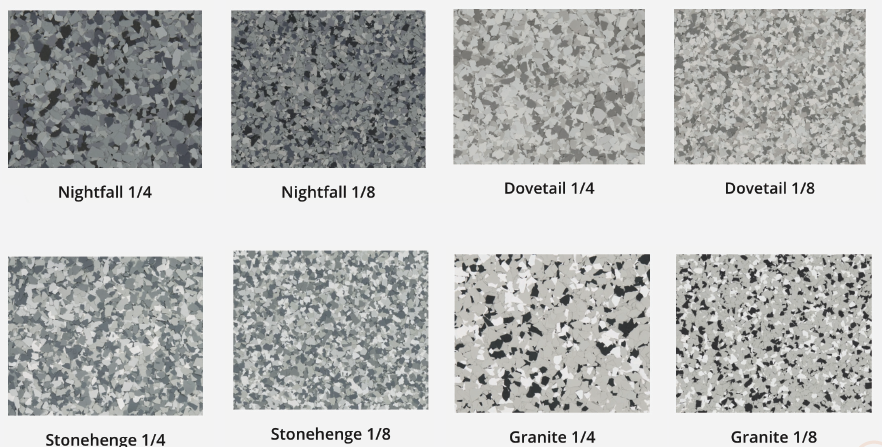

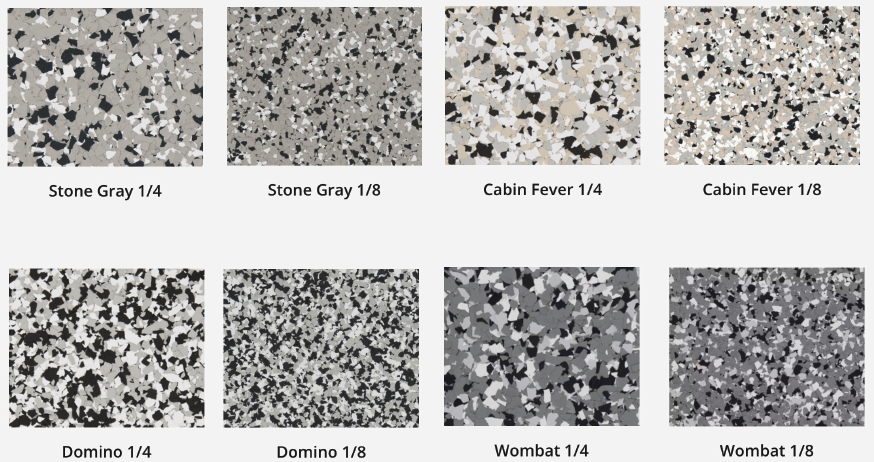

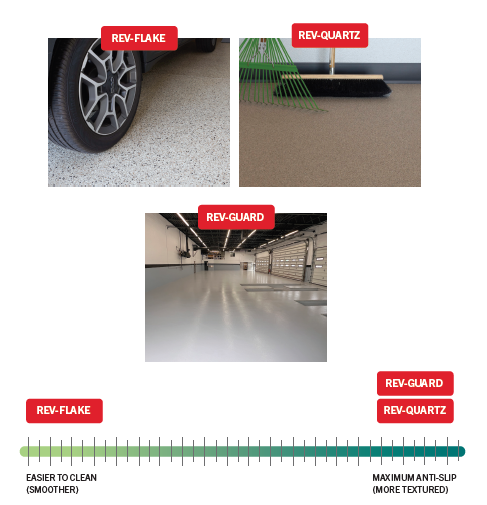

Choosing Your Ideal Floor

Decorative Finish Options To Suite Your Needs

COLOR & FLAKE CHOICES

|  |  |

READ OUR CUSTOMER TESTIMONIALS

-

"The final result was better than expected."

Rarely does an experience with a contractor, any contractor, exceed expectations. But in this case, it did.

Stephen T. -

"These guys are awesome and highly recommend"

The design process was straightforward and creative and the installation was exactly as described (timeline and efficiency).

Matthew O. -

"Very friendly, very professional sales and installation crew."

Able to accommodate a last-minute floor-pattern change. Left me a few spare tiles, per my request.

Satisfied Customer -

"Extremely professional job."

Revel did everything right from the diamond grinder surface prep to the final polyaspartic clear coating with non-slip additives.

Mark F. -

"It was a GREAT decision."

Their estimator/salesman Ryan showed up on time for both appointments.

Mike L. -

"It exceeded my expectations."

It went exactly the way Jeff said it would go

Satisfied Customer -

"I liked their process the best."

From start to finish, working with Revel Garage was a great experience for installing an epoxy system for my garage floor.

Jim C. -

"All the work was completed exactly as specified"

Jeff and the team at Revel were great. I was contacted promptly after my initial request for information, and we were able to set up a video call to go over the services as well as a virtual inspection of the site.

Satisfied Customer

.2102191138550.jpeg)

.2102191138550.jpeg)

.2102191138550.jpeg)

.2102191139550.jpeg)

.2102191139550.jpeg)

.2102281743550.jpeg)

.2102191139550.jpeg)